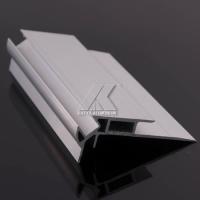

Green Anodized Customize Size , Length Curtain Rod Aluminum OEM

Material Profile

Product Description

Packing : Protect film for each profile, shrink film / kraft paper

exterior for each bundle or pack as customer request.

FOB port: Foshan, Shenzhen, Guangzhou

Delivery time: 15-20 days after receiving the deposite.

Payment term: 30% deposite and 70% balance after the delivery

Material: 6063 Alloy

Temper: T5

Brand name: Kaiyamei Aluminum

Finish: Mill Finished, Anodizing, Electrophoresis, Powder Coating

,Polish, Wood grain, Sand Blasting

Color: Clear Satin, Bronze, Black, Golden, Silver,

Thickness: 0.8mm - 1.5mm

MOQ: 500KG.

Size: Customize size, or use our factory drawing.

Length: 5.8-5.98m, or as customer's request

Sample delivery: Two weeks (one week for mould +one week making

sample)

Sample design: It is better we can get your drawing or sample, we

mainly make according to your design, and we can keep confidential

for your design.

Maximum extruder machine: 8000 tons; Minimum extruder machine: 500

ton

If the profiles are customized, we will make the sample first,

after we get the confirmation from you, we will start production.

Our profiles advantages

Complex integral shapes

| Cost effective

|

Low tooling costs

| Design flexibility |

Versatility in joining

| Machinable |

Rapid prototyping

| Short delivery |

Wide range of finishes

| Plenty of patterns and colors for your choice. |

| Strict control for surface finish, very little scratch. | Accurate mold as well as accurate size.

|

| Standard alloy composition | Both ends of the profiles are very plain and with no burr. |

Aluminum profile surface treatment

Anodized surface treatment

Anodized surface treatment: minimum partial thickness of coating on

decorative surface around 8μm - 10μm.

|

Electrophoretic coating surface treatment

Class | Film thickness um |

| Local thickness of anodize oxide film um | paint film local film thickness um | complex film local film thickness um |

| A | ≥9 | ≥912 | ≥21 |

| B | ≥9 | ≥7 | ≥16 |

Note: Electrophoretic paint profiles are supplied at B level, and

other grades can be supplied as required by customers.

|

FQA ♦

Q1: What is aluminum extrusion, fabrication, and anodization?

A: Aluminum Extrusion refers to a process of creating shapes with

an aluminum billet or log by forcing it to flow through a shaped

opening in a die. Aluminum can be extruded into standard shapes or

specific designs depending on a customer’s preference.

Aluminum Fabrication refers to building aluminum components by

cutting, drilling, slotting, tapping,bending, CNC machining,

mechanical assembly and welding.

Aluminum Anodization is an electro-chemical process of coating

aluminum with a thin layer of oxide to increase corrosion

resistance and harden the surface.

Aluminum also can be dyed with various anodizing colours,which in

most widely used is Brone shades.

Q2: What’s the thickness for anodizing? Can you do 15um?

A: Our normal thickness is about 10 um. Yes, we can do 15um and

above.

Q3: What color you can do for powder coating? The thickness for

powder coat?

A: We can do any color for powder coat as long as you can provide

the color sample. Our normally powder coating thickness is 60-80um.

Q4: What color you can do for wood grain?

A: Our most popular colors are Western Red Cedar, Australia Cedar,

Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western

Wood, Snow Gum, etc. If you need any other colors, we can do

according to the color samples you provide.

Q5: What’s the delivery time for samples and mass production?

A: (1). 2-3 weeks to open the new moulds and make samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the

order.

Our company :

Foshan Kaiya Aluminum Co., Ltd is a comprehensive and professional

enterprise integrating research, design production and sales of

aluminium extrusion profiles for construction and industrial

applications. There are currently 24 aluminum extrusion process

lines at 500MT TO 2500MT, 5 process lines for anodizing, 3 process

lines for powder coating, 2 process line for painting, 2process

line of polishing and brushing. We still have 2 packing line. Our

annual production capacity has reached 80,000 tons which is at the

forefront of the aluminium industry in China.